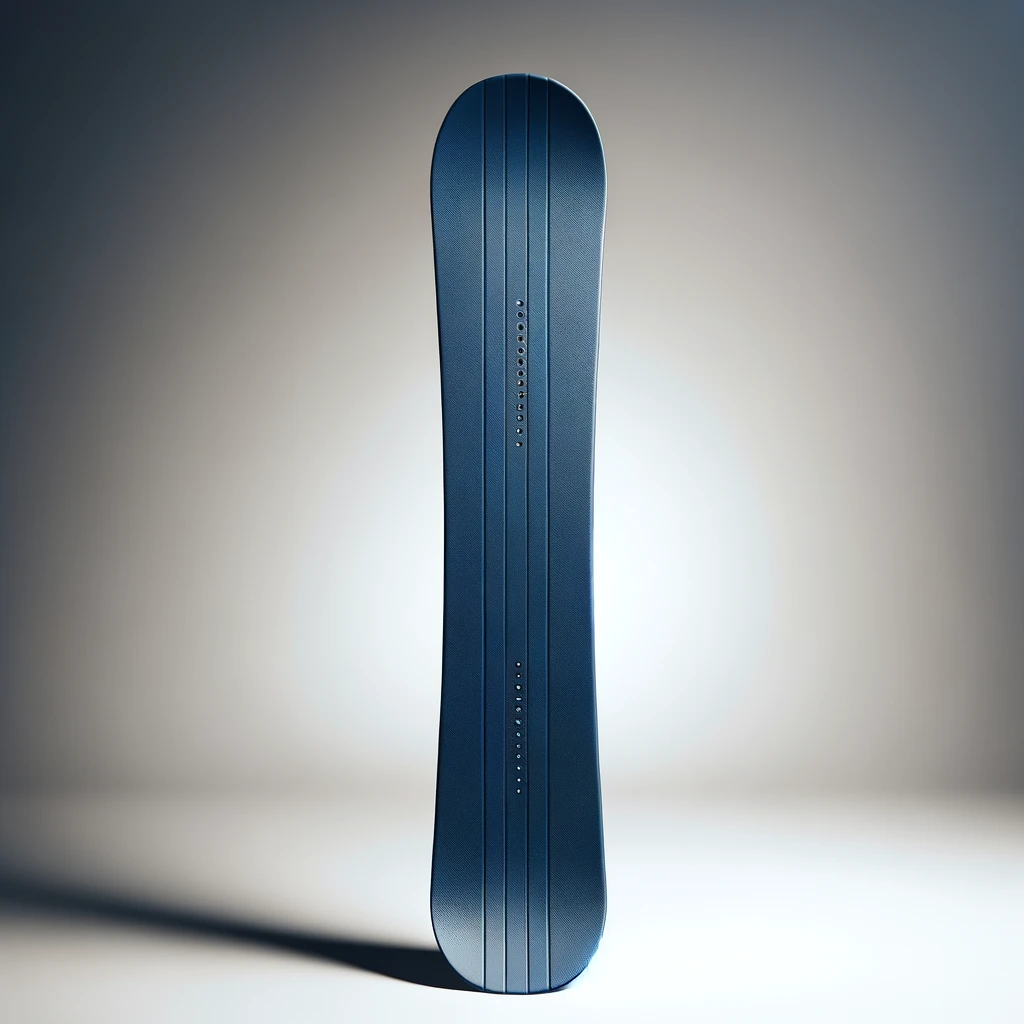

How are Snowboards Designed?

In the snowboard manufacturing industry, the design process is a meticulous blend of art and engineering, aimed at creating boards that not only look good but also perform exceptionally well. Many manufacturers employ a team of professionals, including designers, engineers, and even pro riders, to develop boards tailored to various riding styles, terrains, and skill levels. Advanced computer-aided design (CAD) software is often utilized to bring these visions to life, allowing for a high level of customization. From adjusting the shape and flex of the board to selecting specialized materials for the core and outer layers, every element can be fine-tuned to meet the specific needs of individual clients. This collaborative and highly customizable approach ensures that each board is not just a piece of sports equipment, but a finely crafted tool designed to enhance the rider’s experience on the slopes.

The Process of Playmaker’s Snowboard Manufacturing

Supreme materials by themselves are not sufficient and not as effective and will not yiled good products without combining them with the right and advanced processes.

Playmaker supports 5 different ways to print graphics on the top and base sheet, from UV DDP to screen printing or sublimating process to die-cutting. The molding is carried out on a press with aluminum tools at high temperature to guarantee the best mechanical properties for the fibers and resin. To complete the snowboard tune-up, we recently acquired our second automatic sanding line for the base sheet to achieve an excellent finish on 100% of our production. The final look, we can apply glossy UV varnish with a touch of matte print to achieve the desired design and appearance.

The Quality

All of these meant nothing without our quality control team and procedure. We are determined to make the best snowboards and only deliver 1st quality products.

We implement a unique quality control process that monitors each stage of manufacuring in our facotry and also at our local suppliers.

Developing and making snowboards is a close collaboration not only with Playmaker but also with our suppliers. We use our knowledge and experience and bring all ideas together to build a long, lasting, and beneficial partnership.